Product Introduction

Heat-resistant PVB film laminated glass is a high-performance glass product, mainly composed of two or more layers of inorganic glass and a layer of PVB (polyvinyl butyral) film. PVB film is used as an intermediate layer and is firmly bonded between inorganic glasses to form an integral composite glass product.

Production Process

1. Material selection Select high-quality glass sheets and select the required thickness according to requirements.

1. Glass cutting Precise cutting to ensure cutting quality and accuracy.

2. Glass edge grinding Fine grinding, edge grinding of cut glass to eliminate sharp edges and fine cracks and improve edge smoothness.

3. Washing and drying Wash the edged glass to remove dust, oil and impurities on the surface to ensure subsequent bonding. Drying is required after washing to prevent moisture from affecting subsequent processing.

4. Tempered The principle is to form a layer of compressive stress on the surface of the glass to avoid glass breakage, so as to improve the strength of the glass, and better resist breakage. Even if broken, it is small particles, which greatly reduces the possibility of injury.

5. Lamination and pressing After cleaning, the glass and the film are laminated, initially pressed, and firmly bonded together with high pressure and strong bonding force to ensure the quality and transparent effect.

6. Quality inspection: strict quality inspection, including appearance inspection, dimension measurement, strength test, etc., to ensure that it meets relevant standards and requirements.

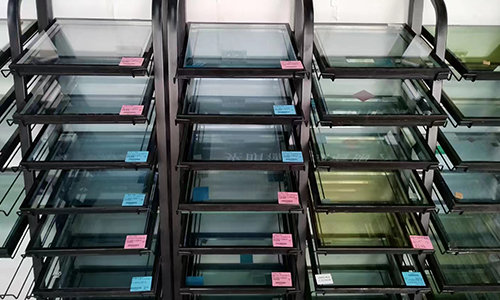

Product Specifications

| Single-layer glass thickness | 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, etc. |

| PVB film thickness | Common PVB film thickness has a variety of specifications such as 0.38~2.28mm, and the specific selection needs to be determined according to the purpose and safety performance requirements of laminated glass. |

| Customized according to customer needs. | |

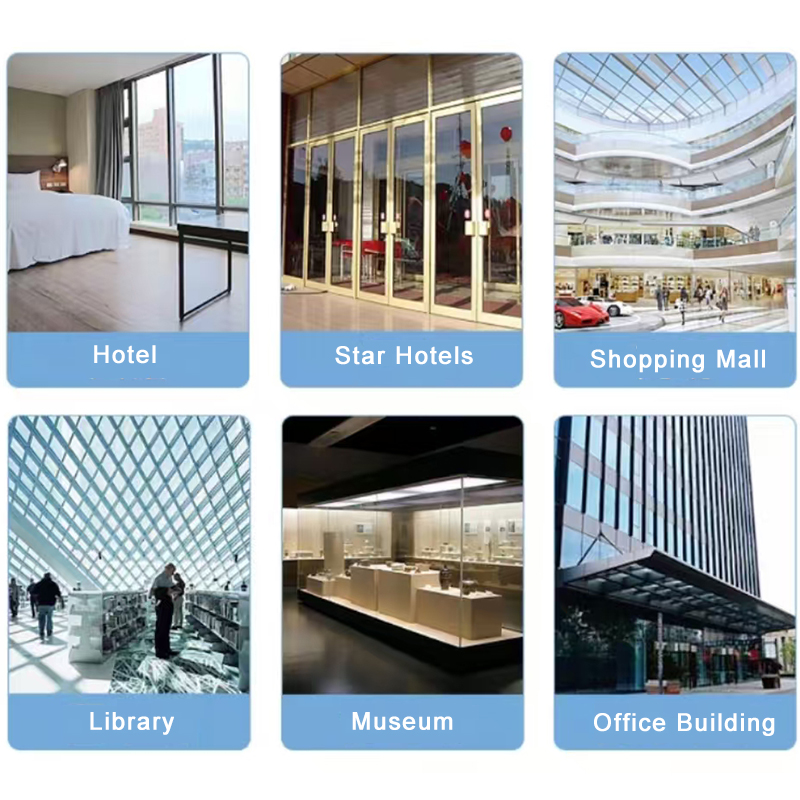

Application

Used in schools, hospitals, libraries, museums, government agencies, office buildings, hotels, restaurants and other places.

Technical Features

Excellent safety performance, significant sound insulation and heat insulation effects, outstanding UV protection, stable heat resistance, etc.

Our Services

Pre-sales service: provide samples;

Welcome to visit the factory; timely reply; professional sales team. Production cycle service: professional customization; timely update of progress; strict quality inspection;

Installation guidance: provide customers with installation guidance services for glass products to ensure the correct installation and use of products.

After-sales service: regular follow-up; provide installation guides; timely solve after-sales problems.

FAQ

Q: What certificates have you passed?

A: After identification by relevant professional institutions, the company has passed 3C certification, environmental protection system certification and other quality system certifications.

Q: Can you provide a quotation?

A: Yes, please provide you with the product name, specifications, and quantity you need, and I will give you a quotation as soon as possible.

Q: How long is the production cycle?

A: After the order is confirmed, delivery within 7-15 days.

Q: What types of glass are there?

Answer: There are single-piece glass, laminated glass, insulating glass, fireproof glass, curtain wall glass, LOWE glass, etc. There are many varieties and they can be customized according to your needs.