Product Introduction

The frosted glass used in office doors and windows is a specially treated glass product.

Production Process

1. Material selection Select high-quality glass sheets and select the required thickness according to requirements.

1. Glass cutting Precise cutting to ensure cutting quality and accuracy.

2. Glass edge grinding Fine grinding, edge grinding of cut glass to eliminate sharp edges and fine cracks and improve the smoothness of the edges.

3. Washing and drying Wash the edged glass to remove dust, oil and impurities on the surface to ensure subsequent adhesion. Drying is required after washing to avoid moisture affecting the subsequent processing.

4. Tempered The principle is to form a layer of compressive stress on the glass surface to prevent the glass from breaking, so as to improve the strength of the glass, better resist breaking, and even if it breaks, it is small particles, which greatly reduces the possibility of injury.

5. Frosting: Use a sandblasting gun to spray abrasives such as diamond at high pressure to impact and cut the glass surface to form a rough frosted surface.

6. Quality inspection: Conduct strict quality inspection, including appearance inspection, dimension measurement, strength test, etc., to ensure that it meets relevant standards and requirements.

Product Specifications

| Thickness | 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, etc. |

| Original sheet specifications | 3300x2440mm, 3050x2740mm, 3660x2630mm, 3660x2740mm, etc. |

| Customized according to customer needs. | |

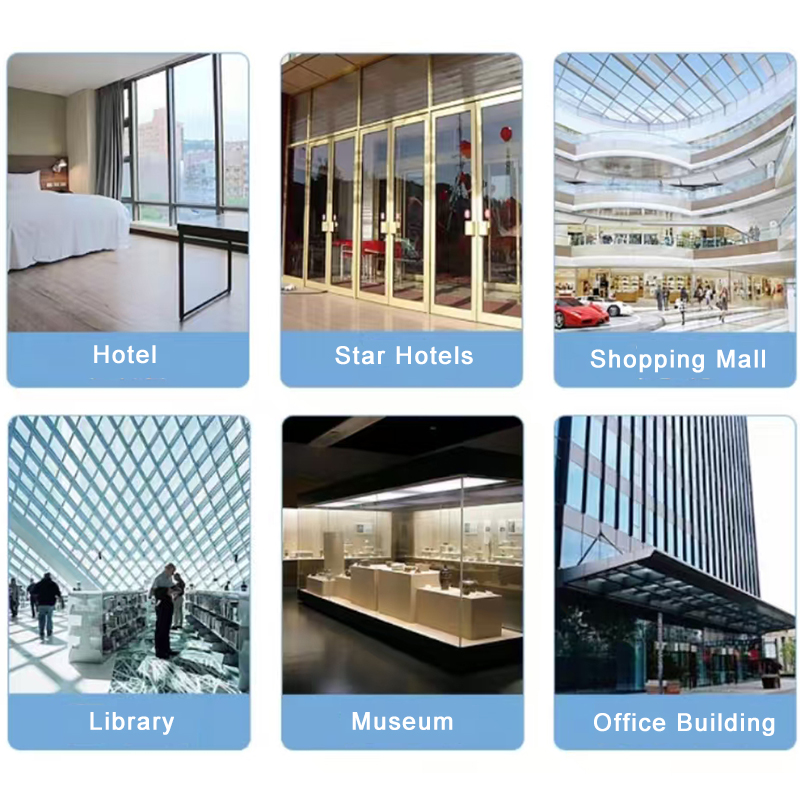

Application

Used in office areas, conference rooms and negotiation rooms, shopping malls and department stores, libraries and reading rooms, hospitals and clinics, etc.

Technical Features

Privacy protection, beauty, safety and environmental protection, sound insulation and heat insulation, durability and easy cleaning, etc.

Our Services

Pre-sales service: provide samples;

Welcome to visit the factory; timely reply; professional sales team. Production cycle service: professional customization; timely update of progress; strict quality inspection;

Installation guidance: provide customers with installation guidance services for glass products to ensure the correct installation and use of products.

After-sales service: regular follow-up; provide installation guide; solve after-sales problems in time.

FAQ

Q:What are the thicknesses of single-pane glass?

A:The thickness of single-pane glass is usually:

3-6mm: common for regular windows, mirrors, and interior decoration.

8-12mm: used for larger areas or scenarios requiring higher strength, such as glass partitions and display cabinets.

Q:Can single-pane glass be processed into tempered glass?

A:Yes.Ordinary single-pane glass can be strengthened through a tempering process, which enhances its strength and makes the small particles formed when it breaks have rounded edges, improving safety.

Q: Are your products certified?

A: Yes, our products are currently ISO compliant and we will also test and certify our products if you require.

Q: Are you the manufacturer?

A: Yes, we are the source factory.

Q: Can you provide customization?

A:Of course, we can provide customization.