Product Introduction

Soundproof and heat-insulating hollow glass is usually composed of two or more layers of flat glass. The glass is bonded and sealed with sealing strips and glass strips through high-strength and high-airtightness composite adhesives to form a sealed space. In this space, inert gas (such as helium, argon, sulfur hexanitride, etc.) can be filled to enhance its sound insulation and heat insulation performance.

Production Process

1. Material selection Select high-quality glass sheets and select the required thickness according to requirements.

2. Glass cutting Precise cutting to ensure cutting quality and accuracy.

3. Glass edge grinding Fine grinding, edge grinding of cut glass to eliminate sharp edges and fine cracks and improve the smoothness of the edges.

4. Washing and drying Wash the edged glass to remove dust, oil and impurities on the surface to ensure subsequent bonding. Drying is required after washing to prevent moisture from affecting subsequent processing.

5. Tempering The principle is to form a layer of compressive stress on the surface of the glass to prevent the glass from breaking, so as to improve the strength of the glass and better resist breaking. Even if it breaks, it is small particles, which greatly reduces the possibility of injury.

6. Aluminum spacer processing and filling desiccant According to the design requirements, use an aluminum strip bending machine to bend the aluminum spacer into a frame. Fill the aluminum spacer with molecular sieves. The function of the molecular sieve is to absorb the moisture in the hollow layer and keep the air dry.

7. Butyl glue and frame gluing Apply butyl glue evenly on the edge of the aluminum spacer to ensure the sealing of the hollow layer. Glue the aluminum spacer coated with butyl glue to the first piece of glass, and then glue the second piece of glass to the other side of the aluminum spacer to form a closed hollow layer.

8. Pressing and applying structural glue The well-mixed insulating glass is sent to the tablet press for pressing, and the glass and the aluminum spacer fit tightly. Apply structural glue on the frame of the insulating glass to enhance the sealing and stability.

9. Quality inspection: strict quality inspection, including appearance inspection, dimension measurement, strength test, etc., to ensure that it meets relevant standards and requirements.

Product Specifications

| Aluminum strip thickness | 6A, 9A, 12A, 15A, 18A, 20A, 22A, 24A, 27A. |

| Single sheet thickness | 5mm, 6mm, 8mm, 10mm, 12mm, etc. |

| Finished product thickness | such as 5mm 9A 5+9A+5 19mm / 8mm 12A 8+12A+8 28mm Original sheet specifications: 3300x2440mm, 3050x2250mm, 3660x2440mm, 3660x2740mm, etc. |

| Customized according to customer needs. | |

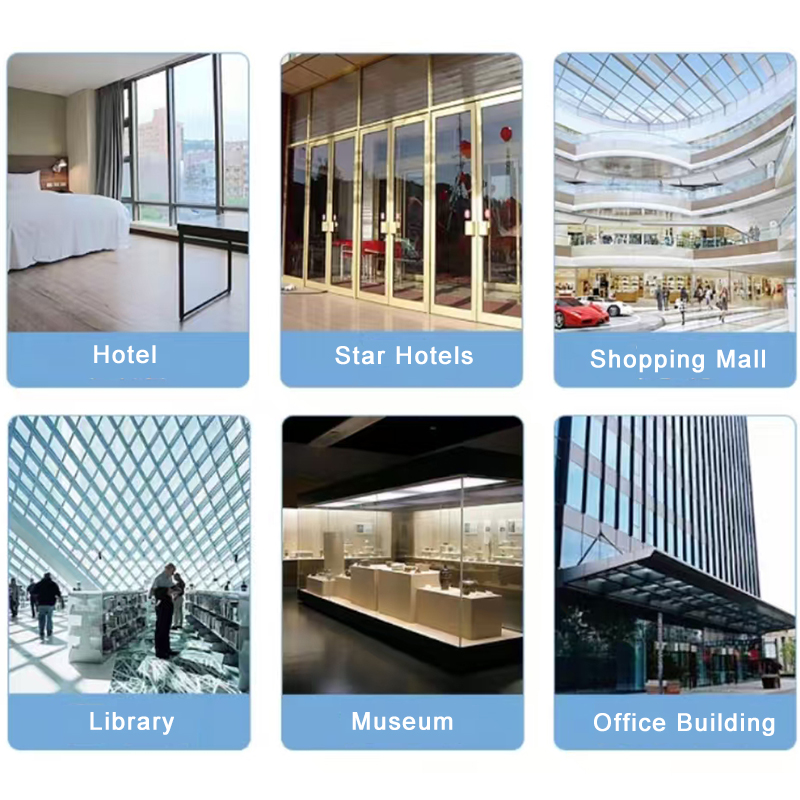

Application

Sound insulation and heat insulation hollow glass is widely used in doors, windows, curtain walls and other locations to improve the sound insulation, heat insulation performance and comfort of buildings.

Technical Features

Excellent sound insulation, excellent heat insulation, anti-condensation, beautiful and durable, etc.

Our Services

Pre-sales service: provide samples;

Welcome to visit the factory; timely reply; professional sales team. Production cycle service: professional customization; timely update of progress; strict quality inspection;

Installation guidance: provide customers with installation guidance services for glass products to ensure the correct installation and use of the products.

After-sales service: regular follow-up; provide installation guides; timely solve after-sales problems.

FAQ

Q:Can insulated glass prevent condensation?

A:Yes. Because of the good thermal insulation properties of insulated glass, condensation caused by indoor and outdoor temperature differences can be reduced.

Q:What are the common thicknesses of insulated glass?

A:The common thicknesses of insulated glass include:

4mm + 12mm + 4mm: two 4mm glass panes separated by 12mm.

5mm + 16mm + 5mm: two 5mm glass panes separated by 16mm.

The thickness can be customized according to actual needs, and the middle air space is usually between 6-20mm.

Q:What are the advantages of insulated glass compared to ordinary glass?

A:Thermal insulation performance: insulated glass reduces heat conduction and provides better indoor temperature control.

Sound insulation: reduces outside noise from entering the building.

Energy saving and environmental protection: reduces energy consumption for air conditioning and heating.

Anti-condensation: the internal hollow design reduces condensation.

Q:Can insulated glass be combined with Low-E glass?

A:Yes. Combining insulated glass with Low-E glass can significantly enhance energy-saving performance, providing both thermal insulation and protection against ultraviolet rays, making it ideal for high-performance building needs.