Product Introduction

As an important part of modern architecture, glass windows not only have basic lighting functions, but also integrate multiple properties such as heat insulation, sound insulation, and anti-theft.

Production Process

1. Material selection Select high-quality glass sheets and select the required thickness according to requirements.

2. Glass cutting Precise cutting to ensure cutting quality and accuracy.

3. Glass edge grinding Fine grinding, edge grinding of cut glass to eliminate sharp edges and fine cracks and improve the smoothness of the edges.

4. Washing and drying Wash the edged glass to remove dust, oil and impurities on the surface to ensure subsequent adhesion. Drying is required after washing to prevent moisture from affecting subsequent processing.

5. Tempering The principle is to form a layer of compressive stress on the surface of the glass to prevent the glass from breaking, so as to achieve the purpose of improving the strength of the glass, and better resist breaking. Even if it breaks, it is small particles, which greatly reduces the possibility of injury.

6. Aluminum spacer processing and desiccant filling According to the design requirements, use an aluminum strip bending machine to bend the aluminum spacer into a frame. Molecular sieves are filled in the aluminum spacer. The function of the molecular sieve is to absorb the moisture in the hollow layer and keep the air dry.

7. Butyl glue and frame gluing Apply butyl glue evenly on the edge of the aluminum spacer to ensure the sealing of the hollow layer. Glue the aluminum spacer coated with butyl glue to the first piece of glass, and then glue the second piece of glass to the other side of the aluminum spacer to form a closed hollow layer.

8. Tablet pressing and structural glue application The well-mixed insulating glass is sent to the tablet press for tablet pressing, and the glass and aluminum spacer are tightly fitted. Structural glue is applied on the frame of the insulating glass to enhance the sealing and stability.

9. Quality inspection: Strict quality inspection, including appearance inspection, size measurement, strength test, etc., is carried out to ensure that it meets relevant standards and requirements.

Product Specifications

| Aluminum strip thickness | 6A, 9A, 12A, 15A, 18A, 20A, 22A, 24A, 27A. |

| Single sheet thickness | 5mm, 6mm, 8mm, 10mm, 12mm, etc. |

| Finished product thickness | such as 5mm 9A 5+9A+5 19mm / 6mm 15A 6+15A+6 27mm Original sheet specifications: 3300x2440mm, 3660x2250mm, 3660x2440mm, 3660x2740mm, etc. |

| Customized according to customer needs. | |

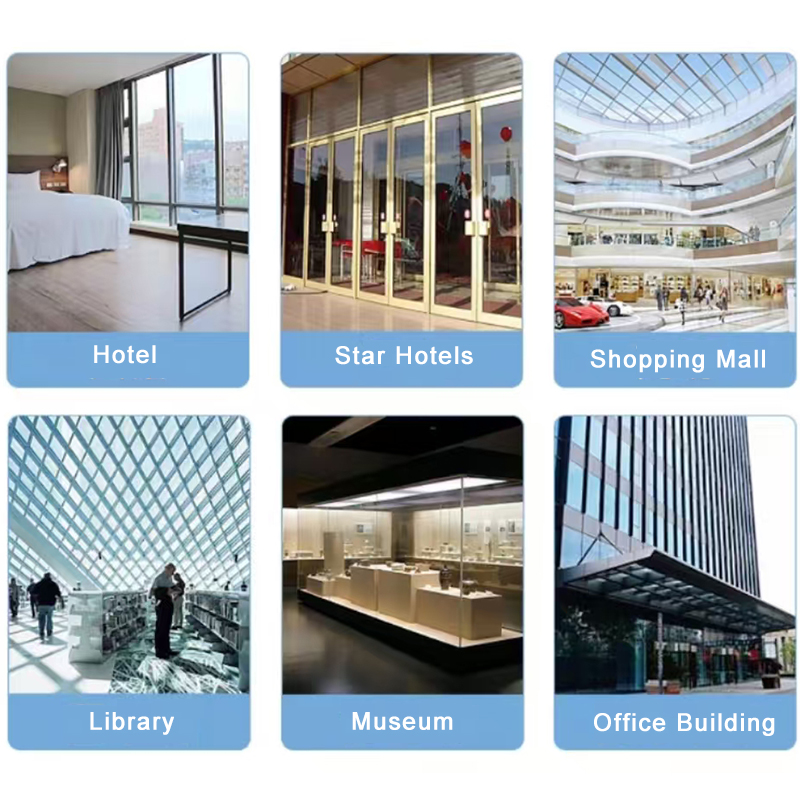

Application

Applied to windows such as balconies, living rooms, bedrooms, offices, conference rooms, schools, hospitals, etc. in the construction field.

Technical Features

Thermal insulation, efficient sound insulation, energy saving and environmental protection, safety and durability, etc.

Our Services

Pre-sales service: provide samples;

Welcome to visit the factory; timely reply; professional sales team. Production cycle service: professional customization; timely update of progress; strict quality inspection;

Installation guidance: provide customers with installation guidance services for glass products to ensure the correct installation and use of the products.

After-sales service: regular follow-up; provide installation guide; timely solve after-sales problems.

FAQ

Q:What is insulated glass?

A:Insulated glass is a glass product consisting of two or more layers of glass separated by spacer bars and sealed along the edges to form a cavity. It provides excellent thermal and sound insulation.

Q: How soon can you give us the quotation?

A:Depending on the product and quantity you want, we will give you a quote as soon as possible.

Q: Can the architectural glass be customized according to the drawing?

A:Of course, we have professional engineers, according to your drawings to give you a quote, do customized products.

Q: Is it possible to visit the factory?

A:Of course. Anytime.